At Knights Foundry, the pattern making process is a critical step in producing high-quality castings. The company utilizes both conventional and CNC methods to create precise and durable patterns tailored to various casting requirements.

In conventional pattern making, skilled craftsmen manually shape materials such as wood, resin, or metal using traditional tools and techniques. This method is well-suited for custom, low-volume, or highly detailed designs that require hands-on expertise.

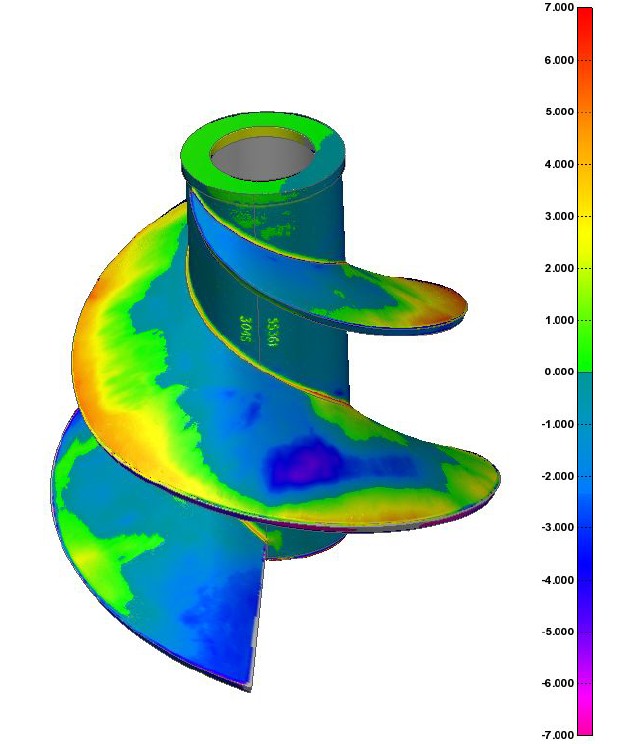

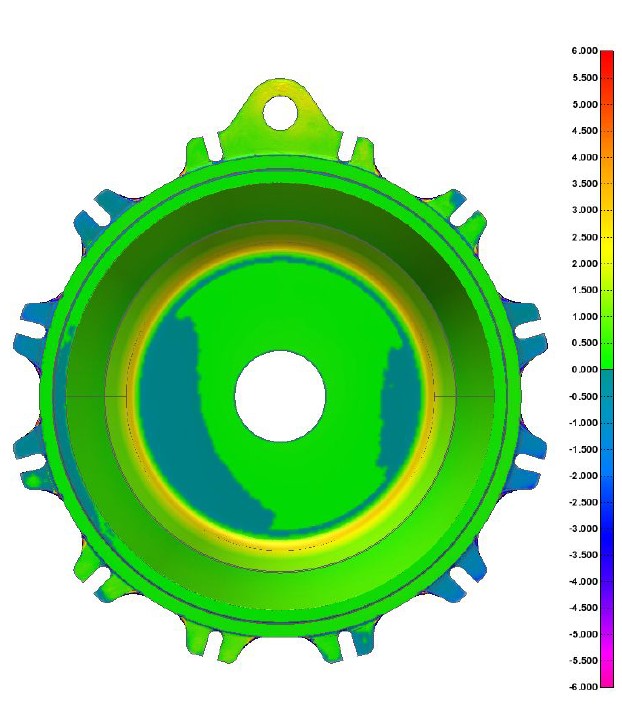

Alternatively, CNC pattern making employs computer-controlled machining to transform 3D CAD models into accurate and repeatable patterns. This method ensures greater precision, faster production, and reduced material waste, making it ideal for high-volume or complex geometries.

Conventional pattern making relies on skilled craftsmanship, where experienced pattern makers manually shape materials like wood, resin, and metal. This method allows for flexibility in one-off or highly customized designs.

In contrast, CNC pattern making leverages computer-controlled machining to produce patterns with exceptional accuracy, repeatability, and efficiency. Using CAD/CAM software, Knights Foundry can rapidly manufacture intricate and complex patterns with tight tolerances, reducing lead times and material waste.

By integrating both traditional craftsmanship and modern CNC technology, Knights Foundry ensures the highest standards in pattern making, catering to diverse industry needs with precision and reliability.

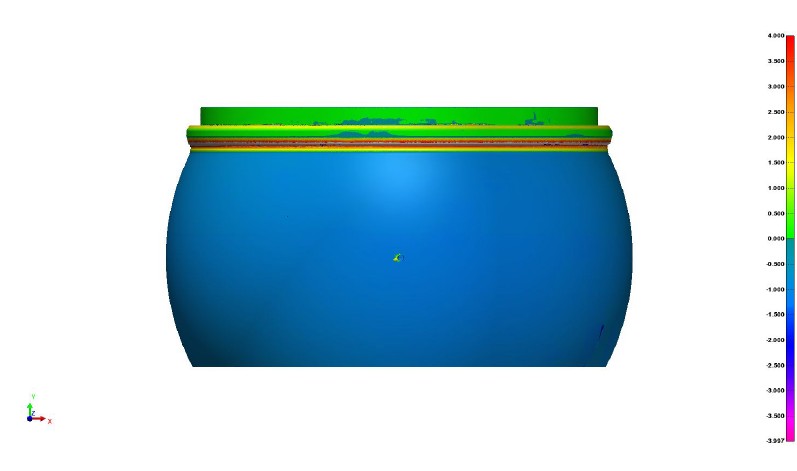

Knights Foundry uses a Unicam CNC router with a 4m x 2m x 400mm bed size to manufacture high-precision casting patterns. The process starts with 3D CAD modeling, where designs are imported into CAM software to generate tool paths.

The CNC router machines materials like wood, resin board, or tooling foam using multi-axis cutting, producing intricate details with tight tolerances. The large bed size allows multiple patterns to be produced simultaneously, improving efficiency and reducing setup time.

Features like high-speed spindles and controlled boundaries ensure accuracy. Once milled, patterns undergo finishing and inspection to meet the foundry's standards before use in casting.

| Material | Advantages |

|---|---|

| Meranti Timber |

Lightweight yet strong, easy to machine and handle. Suitable for manual and CNC machining with a smooth finish. Cost-effective for one-off or low-production patterns. Can be sealed and coated to improve durability. |

| Plywood |

Offers good stability with minimal warping. Great for large or multi-piece patterns. Compatible with both hand tools and CNC machining. Stronger than softwood yet lightweight. |

| Resin (Polyurethane & Epoxy) |

High durability and wear resistant, ideal for high-volume production. Excellent dimensional stability for precision patterns. Machinable with tight tolerances and smooth finishes. Moisture and chemical resistant. |

| Necuron (High-Density Urethane) |

Stable and precise, perfect for CNC machining. Available in multiple densities for various casting needs. Minimal expansion, ensuring accuracy. Easy to shape, sand, and finish. |

| Plastics (ABS, HDPE, Acrylic) |

Lightweight and machinable. Impact-resistant and durable. Moisture and corrosion-resistant. Certain plastics offer heat resistance. |

By utilizing a variety of materials such as meranti, plywood, resin, necuron, and plastics, Knights Foundry ensures each pattern is crafted with the highest level of precision, durability, and efficiency to meet customer-specific casting requirements.